2017

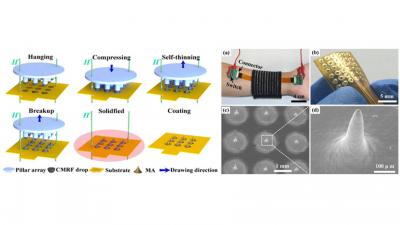

Flexible microneedle array electrode using magnetorheological drawing lithography for bio-signal monitoring

Lei Ren, Qing Jiang, Zhipeng Chen, Keyun Chen, Shujia Xu, Jie Gao, Lelun Jiang* Sensors and Actuators A: Physical Volume 268, 1 December 2017, Pages 38-45 原文链接:https://doi.org/10.1016/j.sna.2017.10.042 Abstract Monitoring and timely intervention are extremely important in the continuous home care. Microneedle array electrode (MAE) have been employed for the long-term bio-signal monitoring without skin preparation. We developed a novel magneto-rheological drawing lithography (MRDL) method to cost-effectively fabricate a flexible micro-needle array electrode (FMAE) for the wearable bio-signal monitoring. Flexible substrate may match closely with curved skin and maintain a stable interface between skin and electrode. The formation mechanism of microneedle array (MA) by MRDL and bio-signal recording performance of FMAE were investigated. MA can be one-step drawn from the droplet array of curable magnetorheological fluid under the assist of external magnetic field. Ti/Au film was coated on the surface of solidified MA to insure the conductivity and compatibility of FMAE. 36-FMAE consists of 6 × 6 micro-needles with an average height of 600 μm and an average tip radius of 12 μm. FMAE with 36 needles (36-FMAE) shows a better bio-signal monitoring performance in some specific situations compared with flexible dry electrode (FDE) and commercial Ag/AgCl electrode. Electrode-skin interface impedance (EII) measured by 36-FMAE is the lowest at a given low input frequency and the amplitude of electrocardiography (ECG) and electroencephalography (EEG) signals recorded by 36-FMAE is the largest. 36-FMAE can collect more distinguishable features and weaken the effect of motion artifact during the dynamical ECG recording. Therefore, 36-FMAE is a promising sensor for the wearable bio-signal monitoring in home care. Keywords: Microneedle array electrode; Drawing lithography; Impedance; Electrocardiography; Electroencephalography; Electromyography

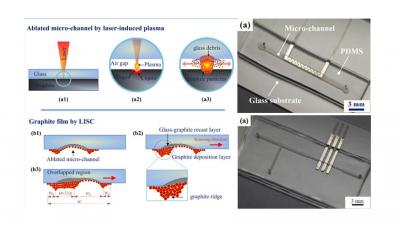

Ultrafast fabrication of micro-channels and graphite patterns on glass by nanosecond laser-induced plasma-assisted ablation (LIPAA) for electrofluidic devices

Shujia Xu, Bin Liu, Chengfeng Pan, Lei Ren, Biao Tang, Qiankun Hu, Lelun Jiang* Journal of Materials Processing Technology Volume 247, September 2017, Pages 204-213 原文链接:https://doi.org/10.1016/j.jmatprotec.2017.04.028 Abstract Electrofluidic devices have attracted tremendous interest in the fields of biology, chemistry and medicine. A laser-induced plasma-assisted ablation (LIPAA) combined with successive electroplating was proposed to fabricate the electrofluidic devices in a fast and cost-effective way. LIPAA can form micro-channels and sputter coat a graphite pattern on glass by tuning of the process parameters. The graphite film can be selectively coated on both the glass and sidewalls of micro-channel by the laser-induced plasma and laser shock. The porous graphite film was composed of a graphite deposition layer and a glass-graphite recast layer. The width of the graphite film can be adjusted by the scanning interval and scanning number. The graphite film has strong adhesion due to the anchor effect and the glass-graphite recast layer. The adhesion strength and conductivity of the metallization pattern can be dramatically enhanced by electroplating Ni on the graphite film. Two electrofluidic devices, including a micro-heater chip and a droplet-based electrofluidic chip, were fabricated and measured, which further demonstrated the flexibility and feasibility of the LIPAA method. LIPAA is promising for the rapid and low-cost fabrication of glass electrofluidic devices. Keywords: Electrofluidic; Glass; Micro-channel; Electrode; Pattern; Nanosecond laser direct-writing; Selective sputter coating; Electroplating

Fabrication of Magnetic Nanofibers by Needleless Electrospinning from a Self-Assembling Polymer Ferrofluid Cone Array

Weilong Huang#, Bin Liu#, Zhipeng Chen, Hongjian Wang, Lei Ren, Jiaming Jiao, Lin Zhuang, Jie Luo and Lelun Jiang* Nanomaterials 2017, 7(9), 277 原文链接:https://doi.org/10.3390/nano7090277 Abstract Magnetic nanofiber has been widely applied in biomedical fields due to its distinctive size, morphology, and properties. We proposed a novel needleless electrospinning method to prepare magnetic nanofibers from the self-assembling “Taylor cones” of poly(vinyl pyrrolidone) (PVP)/Fe3O4 ferrofluid (PFF) under the coincident magnetic and electric fields. The results demonstrated that a static PFF Rosensweig instability with a conical protrusion could be obtained under the magnetic field. The tip of the protrusion emitted an electrospinning jet under the coincident magnetic and electric fields. The needleless electrospinning showed a similar process phenomenon in comparison with conventional electrospinning. The prepared nanofibers were composed of Fe3O4 particles and PVP polymer. The Fe3O4 particles aggregated inside and on the surface of the nanofibers. The nanofibers prepared by needleless electrospinning exhibited similar morphology compared with the conventionally electrospun nanofibers. The nanofibers also exhibited good ferromagnetic and magnetic field responsive properties. Keywords: ferrofluid; self-assembling; needleless electrospinning; magnetic nanofibers

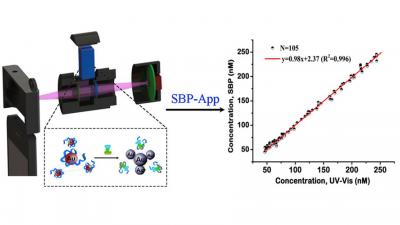

A 3D printed smartphone optosensing platform for point-of-need food safety inspection

Zhonggang Liu, Yali Zhang, Shujia Xu, Heng Zhang, Yixun Tan, Chenming Ma, Rong Song, Lelun Jiang*, Changqing Yi* Analytica Chimica Acta Volume 966, 8 May 2017, Pages 81-89 原文链接:https://doi.org/10.1016/j.aca.2017.02.022 Abstract The deficiency in rapid and in-field detection methods and portable devices that are reliable, easy-to-use, and low cost, results in the difficulties to uphold the high safety standards in China. In this study, we introduce a rapid and cost-effective smartphone-based method for point-of-need food safety inspection, which employs aptamer-conjugated AuNPs as the colorimetric indicator, and a battery-powered optosensing accessory attached to the camera of a smartphone for transmission images capture. A user-friendly and easy-to-use Android application is developed for automatic digital image processing and result reporting. Streptomycin (STR) is selected as the proof-of-concept target, and its specific quantitation can be realized with a LOD of 12.3 nM (8.97 μg kg−1) using the reported smartphone-based method. The quantitation of STR in honey, milk and tap water confirm the reliability and applicability of the reported method. The extremely high acceptance of smartphone in remote and metropolitan areas of China and ease-of-use of the reported method facilitate active food contaminant and toxicant screening, thus making the implementation of the whole food supply chain monitoring and surveillance possible and hence significantly improving the current Chinese food safety control system. Keywords: Smartphone optosensing device; Gold nanoparticles; Two-color ratiometric method; Streptomycin; 3D printing; Point-of-need food safety inspection

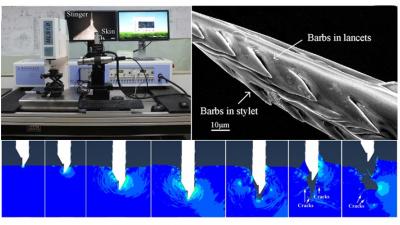

Effect of honeybee stinger and its microstructured barbs on insertion and pull force

Jintian Ling, Zhenhua Song, Jiarui Wang, Keyun Chen, Jiyu Li, Shujia Xu, Lei Ren, Zhipeng Chen, Dianwen Jin, Lelun Jiang* Journal of the Mechanical Behavior of Biomedical Materials Volume 68, April 2017, Pages 173-179 原文链接:https://doi.org/10.1016/j.jmbbm.2017.01.040 Abstract Worker honeybee is well-known for its stinger with microscopic backward-facing barbs for self-defense. The natural geometry of the stinger enables painless penetration and adhesion in the human skin to deliver poison. In this study, Apis cerana worker honeybee stinger and acupuncture microneedle (as a barbless stinger) were characterized by Scanning Electron Microscope (SEM). The insertion and pull process of honeybee stinger into rabbit skin was performed by a self-developed mechanical loading equipment in comparison with acupuncture needle. In order to better understand the insertion and pull mechanisms of the stinger and its barbs in human multilayer skin, a nonlinear finite element method (FEM) was conducted. Experimental results showed that the average pull-out force of the stinger was 113.50 mN and the average penetration force was only 5.75 mN. The average penetration force of the stinger was about one order of magnitude smaller than that of an acupuncture microneedle while the average pull-out force was about 70 times larger than that of an acupuncture microneedle. FEM results showed that the stress concentrations were around the stinger tip and its barbs during the insertion process. The barbs were jammed in and torn the skin during the pull process. The insertion force of the stinger was greatly minimized due to its ultrasharp stinger tip and barbs while the pull force was seriously enhanced due to the mechanical interlocking of the barbs in the skin. These excellent properties are mainly a result of optimal geometry evolved by nature. Such finding may provide an inspiration for the further design of improved tissue adhesives and micro-needles for painless transdermal drug delivery and bio-signal recording. Keywords: Microneedle; Stinger; Barb; Penetration Force; Pull Force; FEM

Fabrication of a Ti porous microneedle array by metal injection molding for transdermal drug delivery

Jiyu Li, Bin Liu, Yingying Zhou, Zhipeng Chen, Lelun Jiang*, Wei Yuan2, Liang Liang* PLoS ONE Volume: 12 Issue: 2 e0172043. 原文链接:https://doi.org/10.1371/journal.pone.0172043 Abstract Microneedle arrays (MA) have been extensively investigated in recent decades for transdermal drug delivery due to their pain-free delivery, minimal skin trauma, and reduced risk of infection. However, porous MA received relatively less attention due to their complex fabrication process and ease of fracturing. Here, we present a titanium porous microneedle array (TPMA) fabricated by modified metal injection molding (MIM) technology. The sintering process is simple and suitable for mass production. TPMA was sintered at a sintering temperature of 1250°C for 2 h. The porosity of TPMA was approximately 30.1% and its average pore diameter was about 1.3 μm. The elements distributed on the surface of TPMA were only Ti and O, which may guarantee the biocompatibility of TPMA. TPMA could easily penetrate the skin of a human forearm without fracture. TPMA could diffuse dry Rhodamine B stored in micropores into rabbit skin. The cumulative permeated flux of calcein across TPMA with punctured skin was 27 times greater than that across intact skin. Thus, TPMA can continually and efficiently deliver a liquid drug through open micropores in skin.

Fabrication of micro-texture channel on glass by laser-induced plasma-assisted ablation and chemical corrosion for microfluidic devices

Chengfeng Pan, Keyun Chen, Bing Liu, Lei Ren, Jiarui Wang, Qiankun Hu, Liang Liang, Jianhua Zhou, Lelun Jiang* Journal of Materials Processing Technology Volume 240, February 2017, Pages 314-323 原文链接:https://doi.org/10.1016/j.jmatprotec.2016.10.011 Abstract A process combined laser-induced plasma-assisted ablation (LIPAA) with chemical corrosion is proposed to fabricate micro-channels with micro-texture surface on glass. Micro-cracks form under the recast layer of glass due to the thermal expansion and contraction strain induced by the plasma during LIPAA. This “defect”, micro-cracks, can be further developed into tree-like micro-textures as the recast layer is removed by chemical corrosion. The effects of chemical corrosion, including corrosive time and corrosive concentration, on the micromorphology of surface texture were investigated. Several representative textures on channel surface were obtained. In order to fabricate micro-channels with micro-texture surface, the effecting factors of LIPAA, including number of scanning cycles, scanning speed, pulse power density and gap distance between glass and sacrificial material, on the channel geometry and chemical corrosive rate were also investigated. The results show that the gap distance is the most significant influence factor on the channel width before chemical corrosion. The corrosive rate of channel width increases with power density and decreases with gap distance. The channel depth before corrosion and its corrosive rate increase with power density and decrease with scanning speed and gap distance. The corrosive rate of width and depth increases with number of scanning cycles till 150, and then reaches steady. The micro-channel with micro-texture surface fabricated by LIPAA and chemical corrosion can be potentially applied in some microfluidic devices. Keywords: Glass; Microfluidic device; Micro channel; Laser-induced plasma-assisted ablation; Chemical corrosion